product details

Nano molybdenum disulfide

Introduction

A solid lubricant or lubricant additive

Compared with conventional molybdenum disulfide, the number of surface atoms in Nano molybdenum disulfide is significantly increased, and more sulfur vacancies are formed, which makes the catalytic activity and selectivity of Nano molybdenum disulfide higher. Nano molybdenum disulfide can be used as a highly active hydrogenation catalyst for heavy oil conversion and fuel oil refining. Nano molybdenum disulfide is used as a catalyst in the process of carbon monoxide methanation with high selectivity and reactivity. Nano molybdenum disulfide is also a catalyst for coal liquefaction.

When used in the petrochemical industry, Nano molybdenum disulfide is a good catalytic hydrodesulfurization catalyst. Nano molybdenum disulfide that meets different functional requirements can be prepared by different methods, such as molybdenum disulfide self-lubricating thin layer, molybdenum disulfide intercalation battery, molybdenum disulfide high-efficiency hydrodesulfurization catalyst, etc. As the particle size of MoS2 becomes smaller, the adhesion and coverage of molybdenum disulfide on the surface of the friction material are significantly improved, and the anti-wear and anti-friction properties of molybdenum disulfide are also doubled. The energy band difference of the ultra-fine Nano molybdenum disulfide thin layer is close to 1.78eV, which matches the energy of light, and has application prospects in photovoltaic cell materials.

Applications of Nano molybdenum disulfide:

Used as a solid lubricant in the mechanical lubrication and friction industries

Excellent lubricity for equipment at high temperature, low temperature, high load, high speed, chemical corrosion and modern ultra-vacuum conditions

Improve lubrication and reduce friction Added in lubricating oils, greases, PTFE, nylon, paraffin, stearic acid

Release agents and forging lubricants for non-ferrous metals

Main performance of Nano molybdenum disulfide:

Large specific surface area, strong adsorption capacity, higher reactivity and stronger catalytic performance

Significantly improve the adhesion and coverage of the friction pair surface

Doubled the anti-wear and anti-wear performance

Typical data of :

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description |

Appearance | grey black powder |

Physical Properties | |

MoS2 (not less than) | 99.9% |

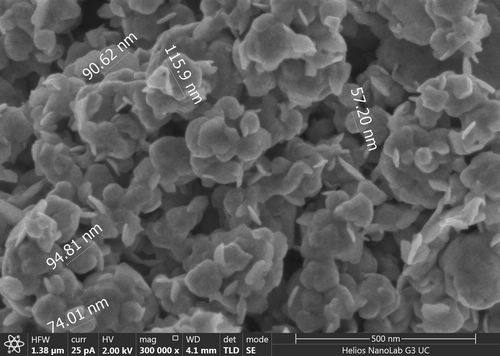

PARTICLE SIZE,nm | 50-300 |

Bulk Density(Scott) | 0.98g/cm3 |

True density | 4.8g/cm3 |

Analysis | |

Inspection Items | Specification |

MoS2 % | 99.90min |

Fe % | 0.0050max |

SiO2 % | 0.0020max |

Pb % | 0.0020max |

H2O % | 0.100max |

SEM(nm) | 100-300 |

Copper Corrosion(3h,100℃) | Qualified |

PH | Neutral |

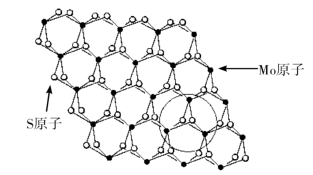

FIG.1 Schematic diagram of the structure of the conventional molybdenum disulfide layer (hexagonal layered structure)

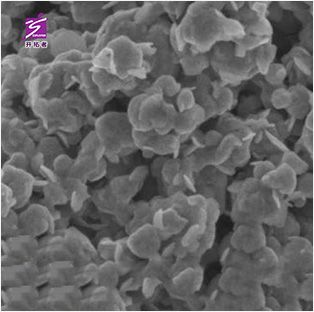

FIG.2 Electron microscope image of Nano molybdenum disulfide.

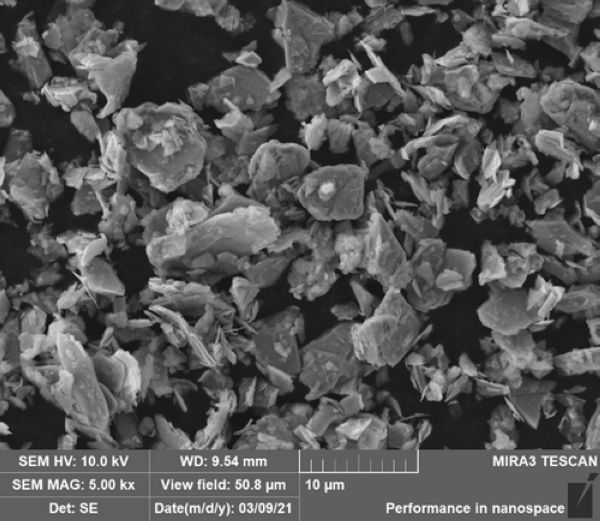

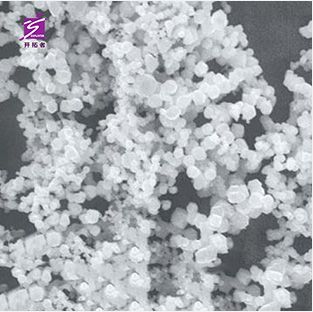

FIG.3 Packing of Nano molybdenum disulfide

Nano molybdenum disulfide are packed in 1kg/bag, 25kg/wood barrel or metal barrel. The inner double layer vacuum packing, the outer metal barrel, 50 kg or 25 kg per barrel. Nano molybdenum disulfide can be produced and packaged according to the user's requirements.

Mobile

Mobile QR code

QR code

MSGS

MSGS